Forklift Learning Studio elevates active learning for engineers

Forklifts are most often used for moving goods and materials, but a new Forklift Learning Studio at Cornell will be used to elevate engineering education, turning the vehicles into interactive tools for studying thermofluids, modeling structural mechanics,and experimenting with control dynamics.

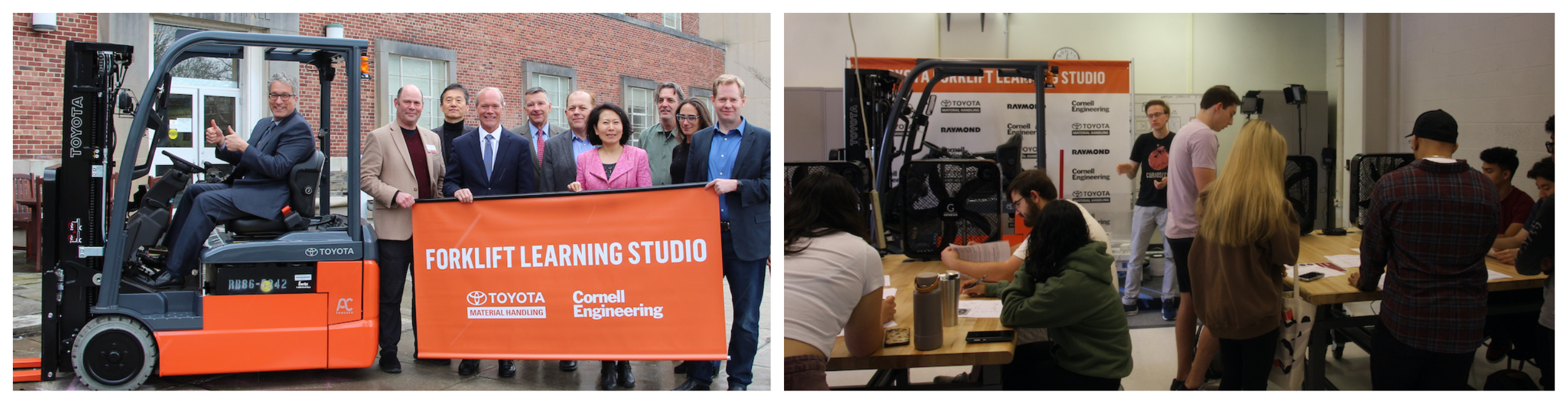

Located on the first floor of Thurston Hall, the studio launched in April thanks to a partnership with Toyota Material Handling, which donated three models of forklifts as well as components and parts. The studio is beingused this fall for ENGRD2020 (statics), MAE3230 (fluid mechanics), and MAE4272 (senior fluids/heat transfer lab).

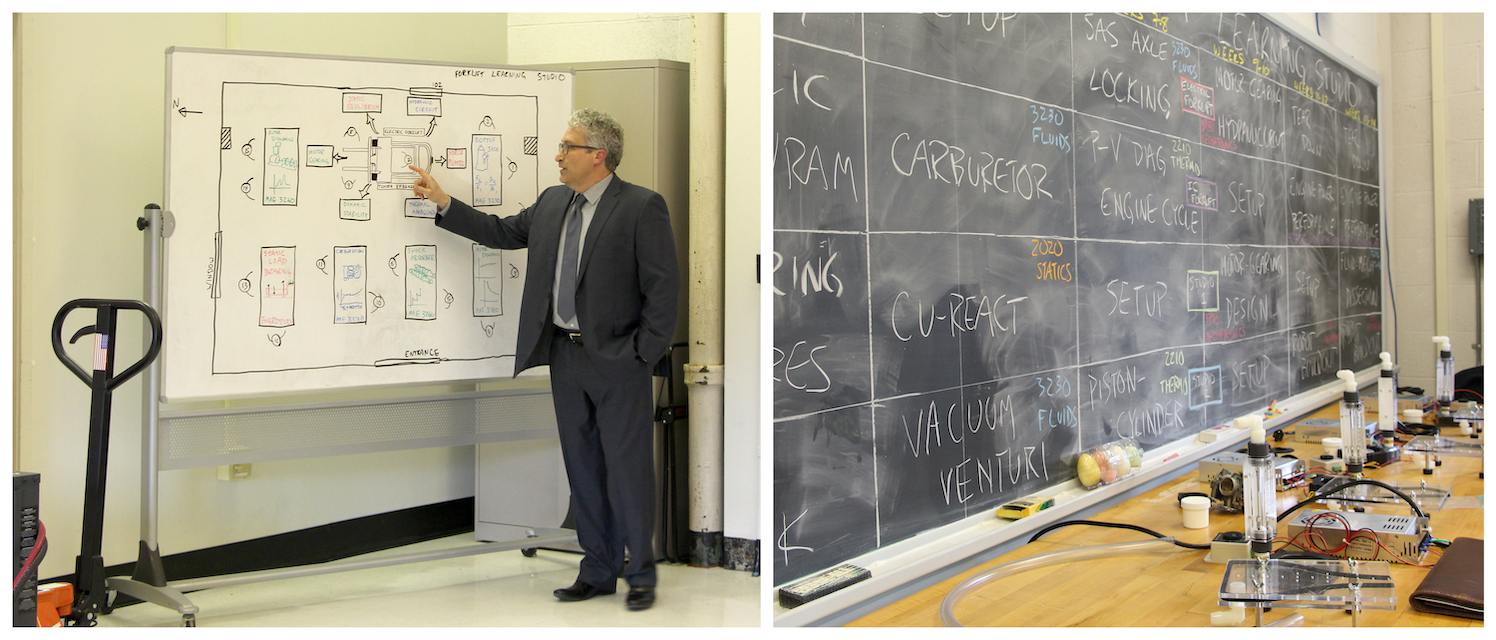

The ForkliftLearning Studio was born from discussions between Brett Wood’85, president and CEO of Toyota Material Handling North America, and Brian Kirby, the Meinig Family Professor in the Sibley School of Mechanical and Aerospace Engineering (pictured left). They wanted to build a learning space using an integrated system with enough complexity to serve a wide range of students, from first-year students to seniors. During summer 2022, Professor Kirby and Matt Ulinski, along with teaching support specialists David Hartino, Liran Gazit, and Patrick Wick, worked with a team of 13 undergraduate and M.Eng.students to build up several aspects of the instructional laboratories.

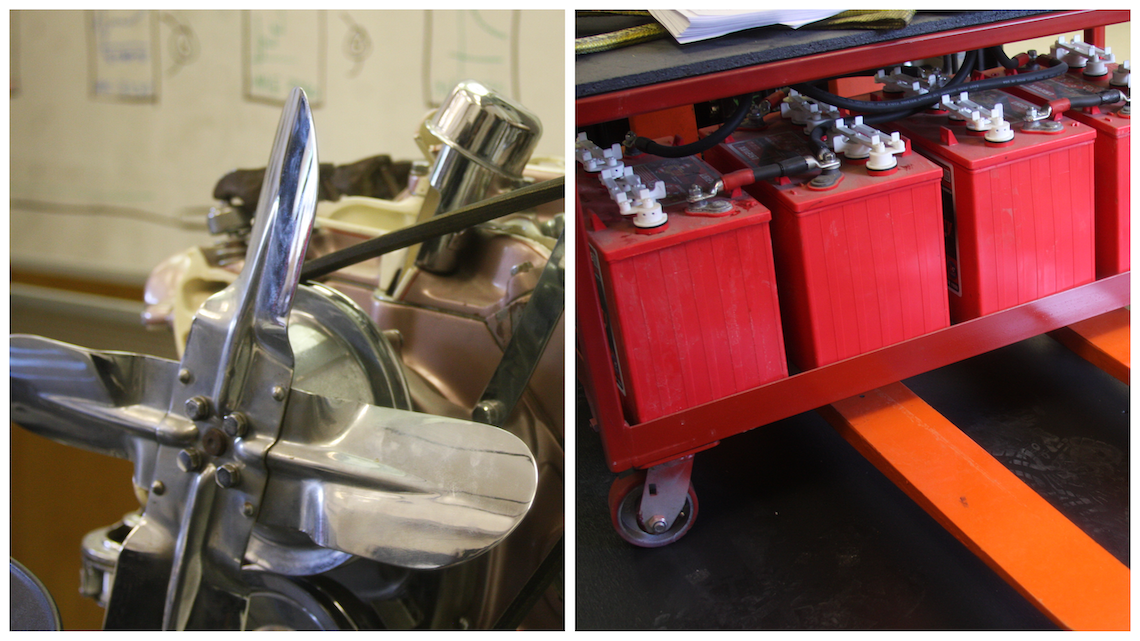

Inside the learning studio, students deconstruct and assemble forklifts and their components to learn about mechanical properties and how they integrate into a larger system. For instance, students might observe the aerodynamic forces of a spinning-cylinder Flettner rotor, while others might get hands-on with a Venturi vacuum system as part of the MAE3230 fluid mechanics course.

In one introductory fluid mechanics lab unit, exercises are aimed at understanding flow distribution. Students use anemometers to measure the flow field of box fans, a large-scale stand-in for a common component in forklifts and many other vehicles and devices. Upcoming lab units will focus on hydraulic jacks and rams, as well as other mechanical systems found in a forklift.“I think students are going to be way more excited about fluid mechanical principles when I teach it next to a forklift with a big hydraulic ram,” Kirby said. “We want students to see the links between fluid mechanics and heat transfer and system dynamics in a way that they don't if the labs are isolated from the class.”